As I've already mentioned in #27, up until the 1970's (in the UK at least) Dunlop and Girling were at the forefront in the design and manufacture of brake systems.

Below are Girling and Dunlop adverts for disc bakes from 1957 car magazines, note that disc brakes had only started to appear on cars around that time.

At the time, Girling was a brand that was part of Lucas, but Dunlop was an independent company that was into tyres for all sorts of transport, as well as anything ***ociated with wheels, such as brakes. As a result, Dunlop were heavily patenting their brake designs.

DUNLOP BRAKE DISC PATENT in Google throws up some interesting information. Some excerpts from Google Books show that Dunlop patented disc brakes for aircraft, and then for cars in the 1950's. One excerpt states that reliable disc brakes first appeared on the Jaguar C-Type (Dunlop design), the Citroen DS, and the Triumph TR3 (Girling).

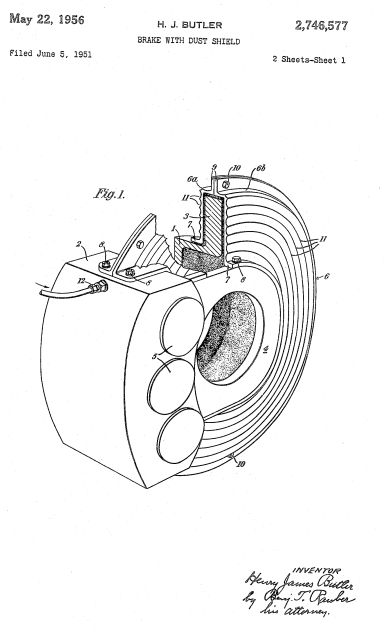

In particular, someone called Henry James Butler was filing the Patents for Dunlop in the US (Dunlop Co must have realised that patenting in the US was imperative). This website

http://www.freepatentsonline.com/ seems to be the best for searching for Patents, particularly in the US. Searching in there for "henry james butler brake" (without quotes) throws up loads of patents, in particular "Brake with dust shield".

Here it is, US2746577

This was first filed in 1951, and as far as I can tell, it is the first patent for a "dust shield" for disc brakes.

As you can see, the disc (diagonal hatching, labelled 1 and 3) is fully enclosed. The pipe 12 is stated to be a source of compressed air, which can be applied to keep the disc cool. Butler starts off by saying that disc brakes are used in aircraft and

implies that they aren't so much of an issue and goes on to say "when a disc brake of the type described hereinabove is used in a road vehicle however, it is found that dust and road dirt adhere to the radially extending sides of the disc with the result that when the brakes are applied, the disc is scored and abraded by particles of grit and the like whilst the pads of friction material are very rapidly worn down". He then says that the patent is to prevent this and states that, in conjunction with the amount of compressed air, heat dissipation would be "optimised" (my wording). He says that the patent is applicable to aircraft, road cars, and large road vehicles.

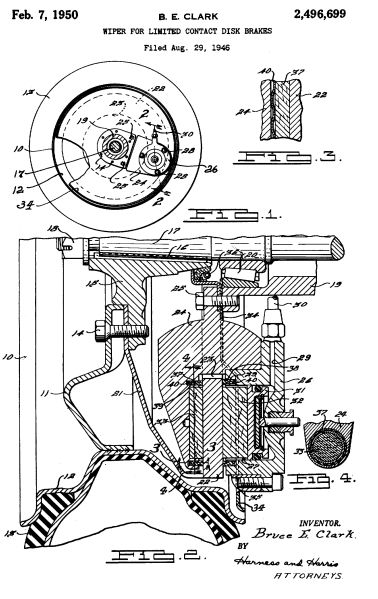

His patent cites 7 other patents: 2 of which are for cooling of drum brakes; 1 for shielding the entire drum (for similar reasons to his patent) ; 2 for single brake disc design; and 1 for a disc wiper (1950, shown below)

Here is the latter, US2496699

Bruce E. Clark (patentee for Chrysler of the above) states "One difficulty with [disc brakes] has been found to be that the portion of the disc which is exposed to the air is also exposed to dust, water, mud, slush, and similar road dirt. The presence of this road dirt on the disc is detrimental when the dirt comes into contact with the friction element. Water and dirt radically change the coefficient of friction of the element on the disc and wear of the parts is accelerated. I have provided means to remedy this defect by preventing the road dirt from coming into contact with the friction disc. I provide a means for cleaning a localised area of the disc and always presenting a clean disc surface in alignment with the friction element. In addition I seal the movable member itself from direct contact with the road dirt."

Of the two designs, IMO the latter is better, but one has to ask

1. why were these types of patent being proposed ?

2. why were they never fully implemented ?

The answers are fairly obvious.

1. in the 1950's disc brakes were new on cars, and these patents were "contingencies" in case such problems became apparent over time

2. (i) in the 1940's and 1950's roads were "un-paved" in many parts of the US and Europe; (ii) the early materials used to manufacture discs and pads may not have been durable; (iii) fabrication and maintenance of the above would have been more difficult than maintenance of the disc and pads themselves

As a result, brake disc shields evolved into something more-or-less resembling an umbrella, and like an umbrella, shields are not going to do a great deal in heavy rain conditions.