Jayaccord

Members

Pedro,

Thank you for the document info. It's a good find. Much appreciated.

Brian,

Thank you for translating the system function. Why is it that it is so hard to get electrical schematics of the Accord diesel? (I see that even Haynes is sparse on the Honda side).

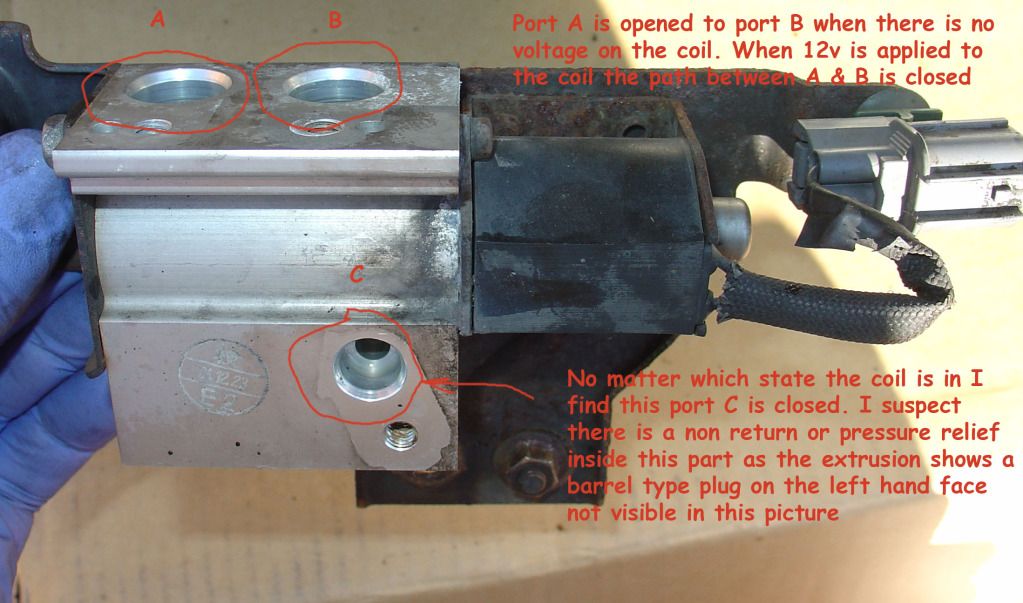

When I transplant the condenser I will confirm the function of that valve (power to open or close).

My gut feeling is the compressor but my head has been trying to avoid it until I have enough facts I guess. I just didn't want to go down the route of changing the condenser and having it recharged only to have to evacuate it again for other works.

Plan now.

1) Get system evacuated

2) Transplant the condenser.

3) Remove the compressor and inspect/replace.

I think I will strip it out to check and just refit if it's faulty until I get a replacement? (Remove the compressor clutch coil relay so it doesn't accidentally get switched on)

I believe the alternator has to be removed to gain access. Is it worth doing the shorter belt mod at the same time? (Read that somewhere).

When I inspect the compressor am I expecting to feel some suction/delivery pressure by simply placing my palm over the ports and spinning the clutch by hand? Or does it have to be quite high speed to feel if it works? Are they easy to strip/rebuild or is it throw away?

Jay

Thank you for the document info. It's a good find. Much appreciated.

Brian,

Thank you for translating the system function. Why is it that it is so hard to get electrical schematics of the Accord diesel? (I see that even Haynes is sparse on the Honda side).

When I transplant the condenser I will confirm the function of that valve (power to open or close).

My gut feeling is the compressor but my head has been trying to avoid it until I have enough facts I guess. I just didn't want to go down the route of changing the condenser and having it recharged only to have to evacuate it again for other works.

Plan now.

1) Get system evacuated

2) Transplant the condenser.

3) Remove the compressor and inspect/replace.

I think I will strip it out to check and just refit if it's faulty until I get a replacement? (Remove the compressor clutch coil relay so it doesn't accidentally get switched on)

I believe the alternator has to be removed to gain access. Is it worth doing the shorter belt mod at the same time? (Read that somewhere).

When I inspect the compressor am I expecting to feel some suction/delivery pressure by simply placing my palm over the ports and spinning the clutch by hand? Or does it have to be quite high speed to feel if it works? Are they easy to strip/rebuild or is it throw away?

Jay