Pacman8184

Members

Haha no problem at all. Just wondered what a diaphragm filter was or is this just another name for the IMRC filter?

A massive thanks for this....had a few irritating issues with the car lately...and beginning to feel a little fed up with it! On my way back from hols noticed the car hunting revs at cruising speeds on the motor way, really disconcerting! Then got the engine fault light.....read by my friendly tech and code P2004 IMRC VALVE STUCK open. Chatted with Fahad and read forum and started with blanking the EGR but the car went into limp mode so couldn't really ***ess the effect as I was limited to 2000rpm. What I did notice is a lot of crud in the inlet manifold! Any way after reading the above I disconnected the IMRC, and this seems to have isolated the problem with the revs! Have agreed with Fahad the EGR still needs blanking off so will book in for next week....just need to decide whether to replace IMRC or MAP out....as I don't really know what it's supposed to do I'm open to advicewaj1974 said:Right guys, the news you all been waiting for. The Frequency Valve WORKS...no jerkiness, no hesitation and above all my car now pulls like it never did before lol anyways guys as promised here are the photos of the fitting etc... I hope it solves many a peoples problems and please please please before buying the EGR like i was make sure it is the part thats faulty as its very expensive and Honda wont take it back.I would also like to say please do not blame the hesitation or jerkiness on the Elite remap as that only highlights the problem which in theory means the part was on its way out anyway. Fahad has done a brilliant job on the remaps and would like him to thank for his great work for all us members with remaps Ok heres the Frequecny Solenoid Valve which i bought from Honda. £116 inc VAT.

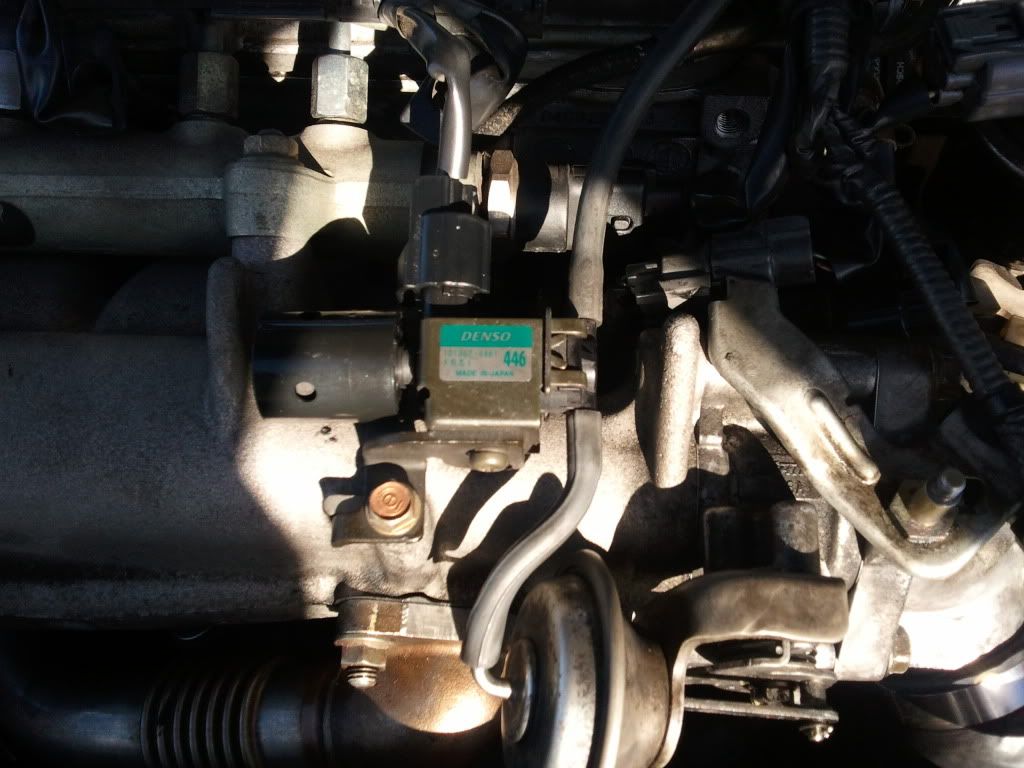

Ok heres the Frequecny Solenoid Valve which i bought from Honda. £116 inc VAT. And here it is in its full glory

And here it is in its full glory The valve attached to the top of the intake manifold i believe

The valve attached to the top of the intake manifold i believe Ok so you unclip the sensor, slide off the vacuum pipes and with a 10mm socket undo the nut and off comes the valve. Fitting is the reversal of removal.

Ok so you unclip the sensor, slide off the vacuum pipes and with a 10mm socket undo the nut and off comes the valve. Fitting is the reversal of removal. I knew straight away when i took it for a drive that it had cured the problem. Ok for other members, this problem was never highlighted for a long time and i wondered for months is it the egr valve, engine cylinder misfire, fuel filter which i changed religiously many a time lol air filter etc etc I only found out when the MIL came on with the code, and a little help from members pointed to the valve. Guys you can all try taking the clip sensor off the valve and if it drives better than you know for DEFINITE that its the problem.Your car will not go into limp mode but will drive better than before. Bear in mind that once you take off the valve sensor clip you dash will throw on CEL, which you need to clear using an OBD2 reader or equivalent.I hope this helps some members out there as i know how frustrating this jerkiness issue is, and if you have found it helpful please dont forget to send me a rep point

I knew straight away when i took it for a drive that it had cured the problem. Ok for other members, this problem was never highlighted for a long time and i wondered for months is it the egr valve, engine cylinder misfire, fuel filter which i changed religiously many a time lol air filter etc etc I only found out when the MIL came on with the code, and a little help from members pointed to the valve. Guys you can all try taking the clip sensor off the valve and if it drives better than you know for DEFINITE that its the problem.Your car will not go into limp mode but will drive better than before. Bear in mind that once you take off the valve sensor clip you dash will throw on CEL, which you need to clear using an OBD2 reader or equivalent.I hope this helps some members out there as i know how frustrating this jerkiness issue is, and if you have found it helpful please dont forget to send me a rep point

Decision made thenF6HAD said:Simon I've mapped them out without issue. On vauxhall and BMW people actually break the flaps out because they're so troublesome.